Form 4

at Blazing Speed

Accurate

Reliable

Intuitive

Versatile

Fast

Industrial Parts

at Blazing Speed

Accurate

Reliable

Intuitive

Versatile

Fast

Industrial Parts

| Form 4 | Benchmark FDM | Benchmark SLA | Form 3+ |

| 2 h 1 m | 3 h 54 m | 3 h 37 m | 8 h 31 m |

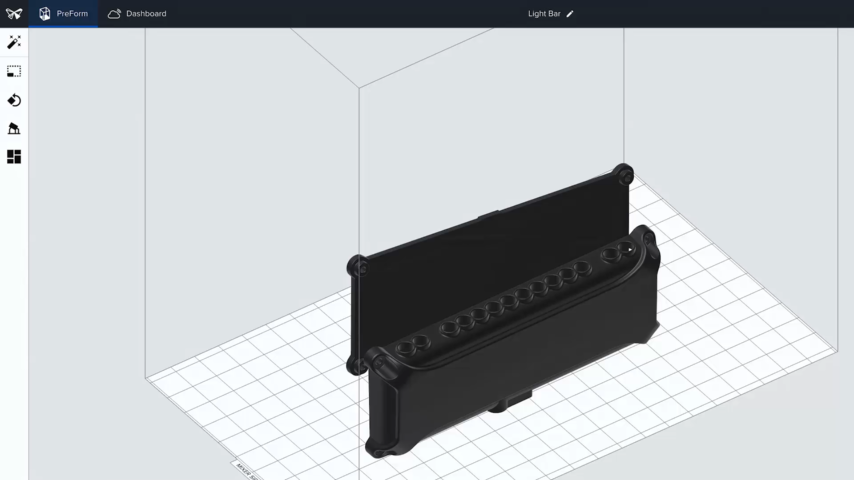

Go from CAD to printing

in minutes with just a few

clicks using the free PreForm

software.

in minutes with just a few

clicks using the free PreForm

software.

Print time is similar whether

you’re printing one part

or a full build of many parts.

you’re printing one part

or a full build of many parts.

*Typical print time using 80th percentile print height (53 mm), 100 µm layer height, and most materials.

Most prints in less than 2 hours!*

Really Fast

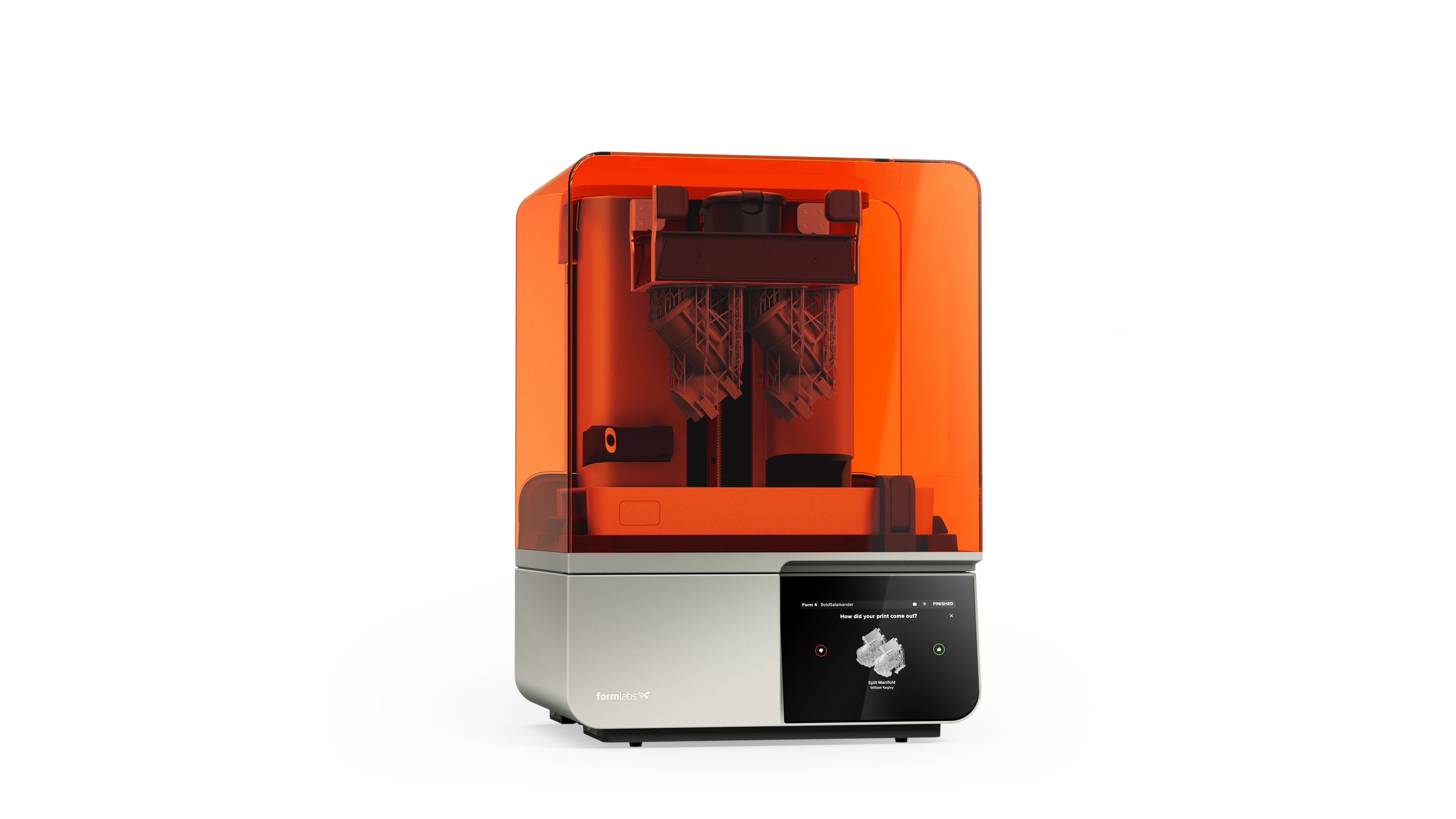

Form 4’s speed is driven by Formlabs’ new Low Force Display™ Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display.

Make a deep dive into the Form 4 to learn more!

Make a deep dive into the Form 4 to learn more!

Jewellery

Engineering & Product Design

Manufacturing

Education

Entertainment

Tackle any problem with the industry-leading materials for different purposes.

Industry-leading materials

Versatile

Learn in 15 minutes!

Intuitive

Unmatched print success rate!

Reliable

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing.

Smoothest Surfaces

±0.15% XY dimensional tolerances so assembles always fit.

Most Accurate Assemblies

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Sharpest Details

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assembles always fit.

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Produce stunning parts that always fit, rivaling injection molded parts.

Rivals injection molded parts

Accurate

Take a 3D tour of the Form 4

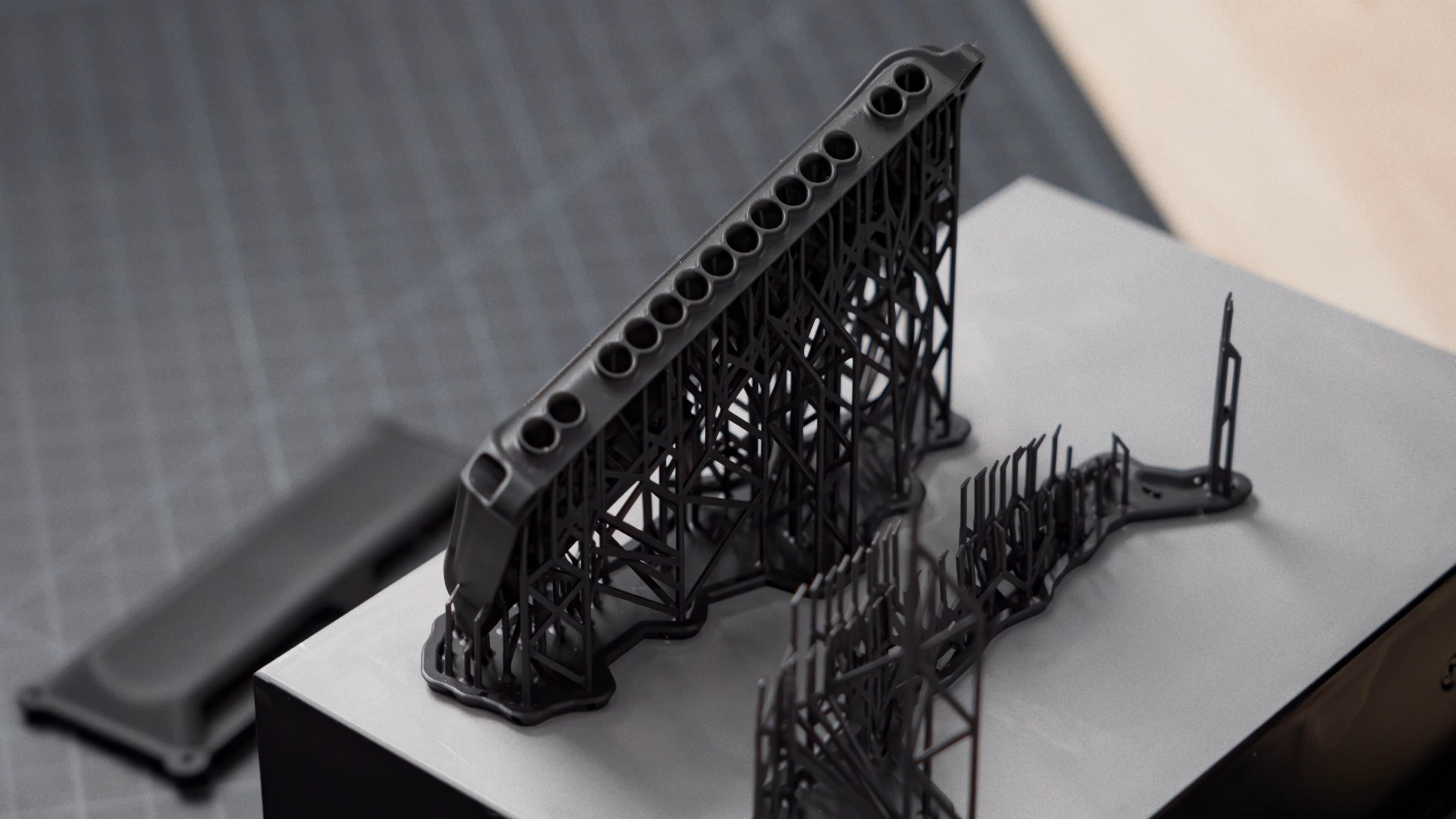

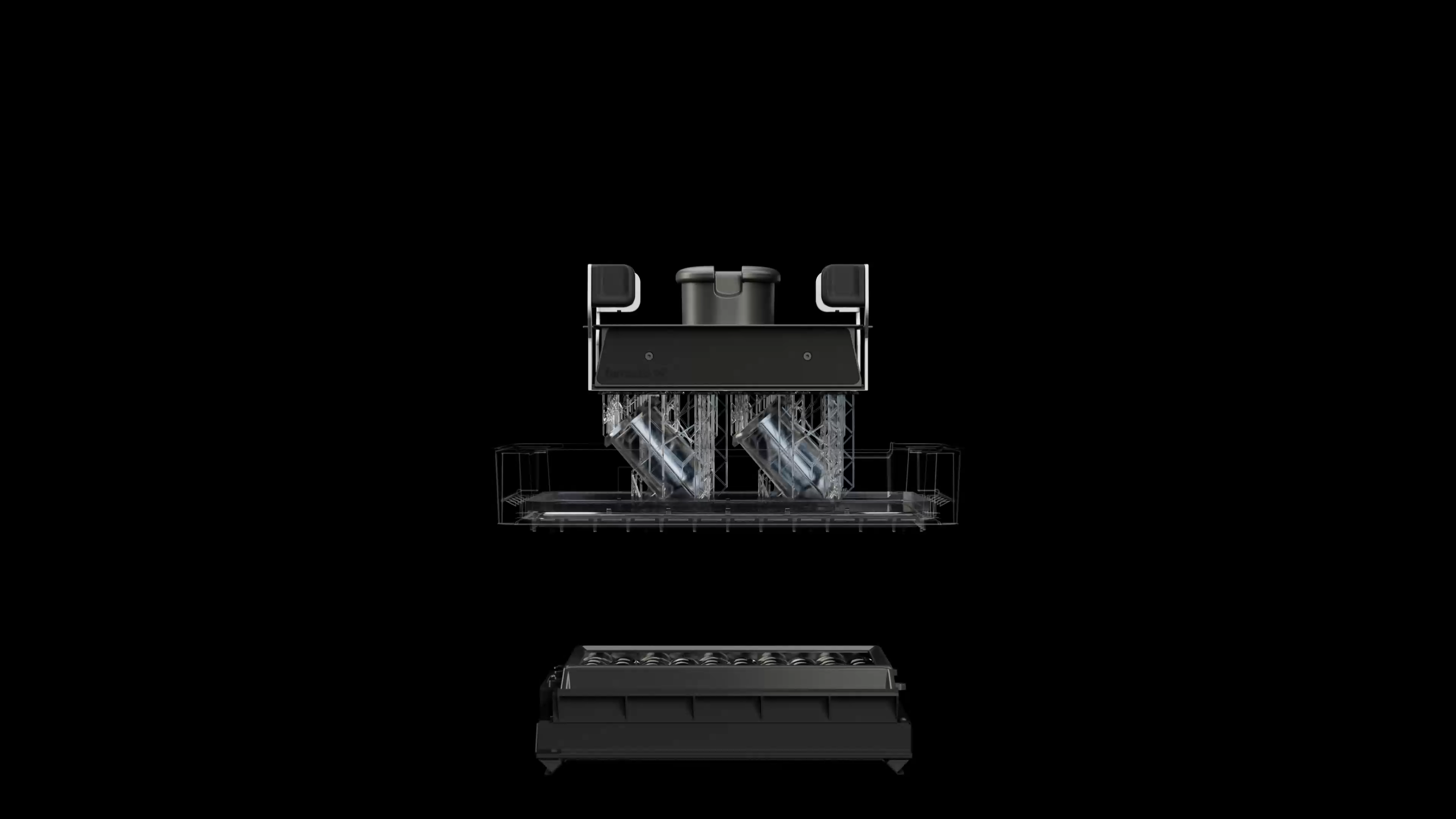

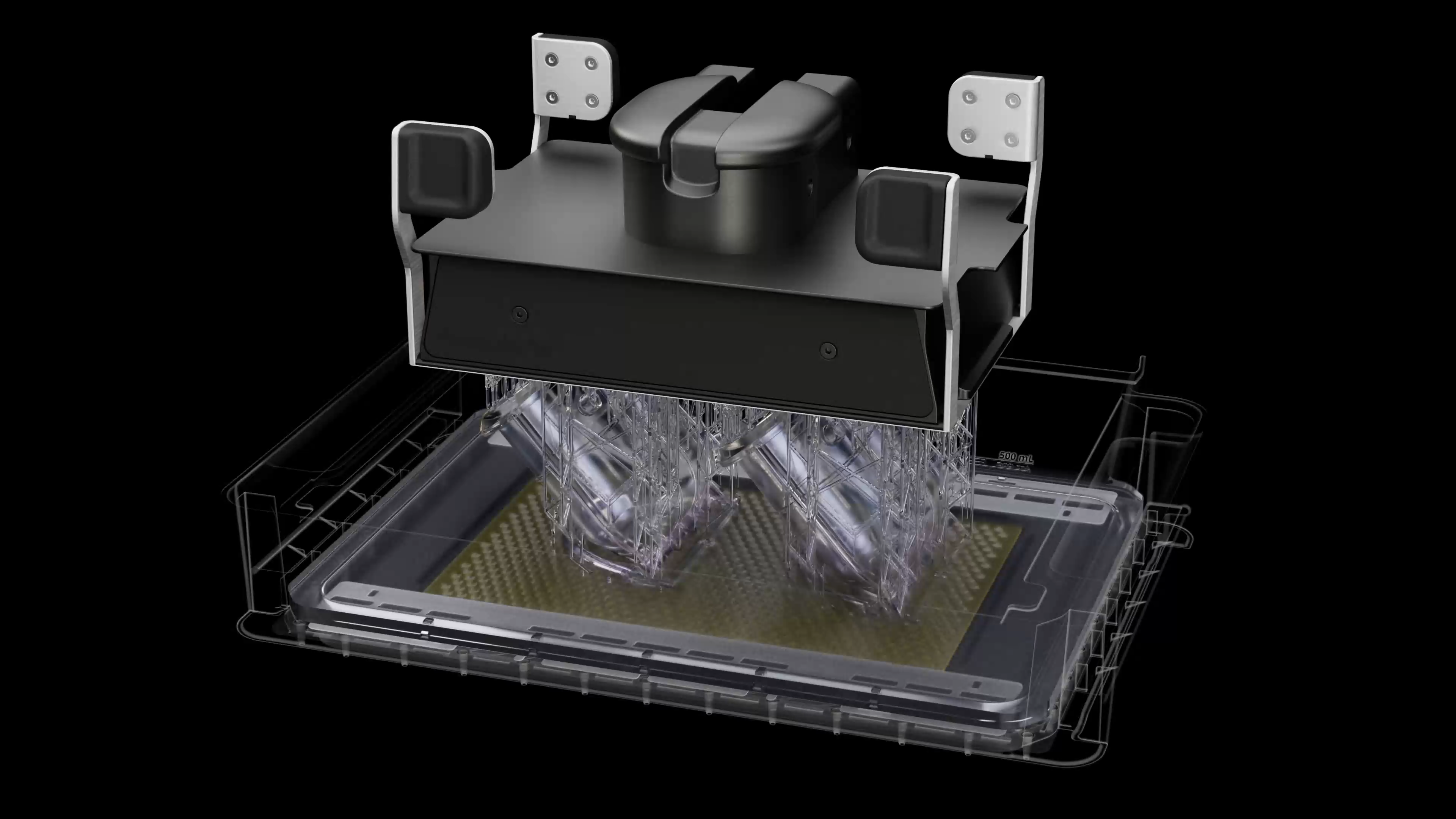

The Backlight Unit generates a uniform area projection of an ultra-high power light using 60 LEDs and collimating lenses. It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform.

- Unmatched optical power: 16 mw/cm² delivered to the print plane.

- Plano-convex lens array and optical baffle creating highly collimated and uniform light, even at high power.

- Extremely long lifetime, due to an integrated cooling system.

The Light Processing Unit 4 (LPU 4)

precisely masks light from the backlight unit into the shape of a printed layer.

Together, the Backlight Unit and LPU 4 enable you to print with extreme speed, accuracy, and print quality anywhere on the build platform.

The LPU 4 is long -lasting, resistant to accidental damage, and easy to replace.

precisely masks light from the backlight unit into the shape of a printed layer.

Together, the Backlight Unit and LPU 4 enable you to print with extreme speed, accuracy, and print quality anywhere on the build platform.

The LPU 4 is long -lasting, resistant to accidental damage, and easy to replace.

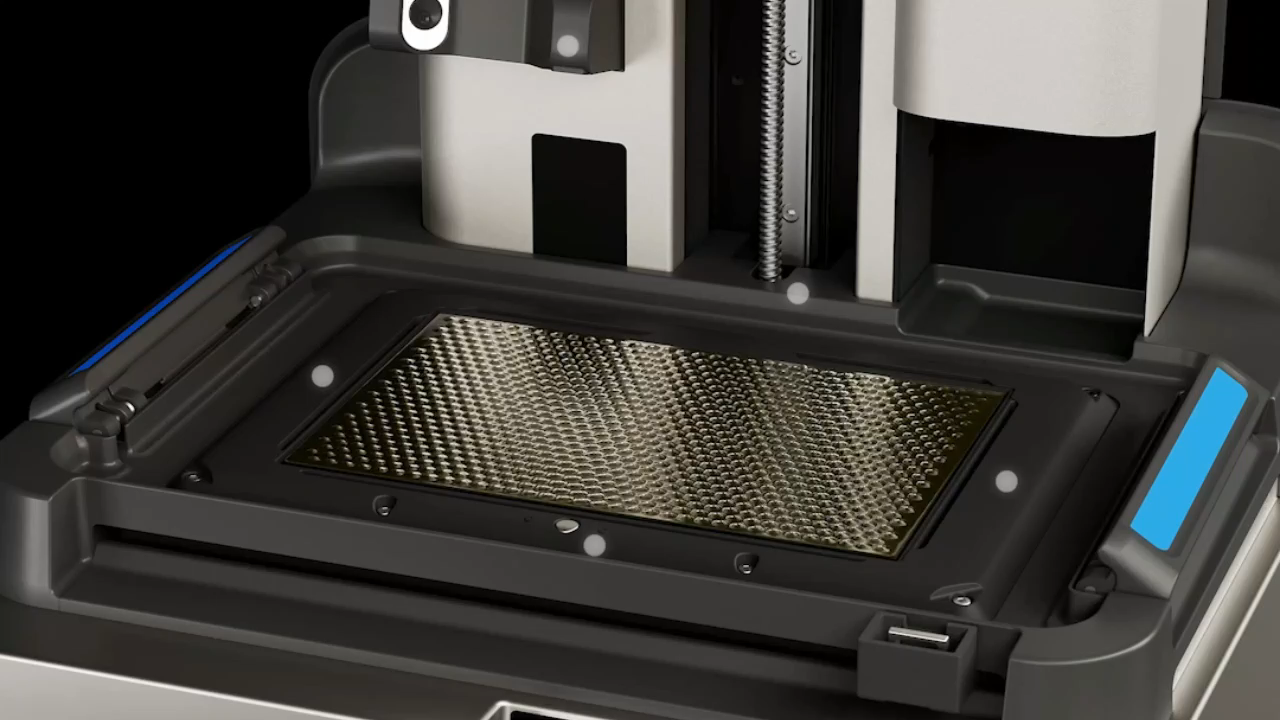

A proprietary, microtextured optical film provides airflow between the resin tank and the Light Processing Unit.

This film is built into the Light Processing Unit and sits at the top of it.

This significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

This film is built into the Light Processing Unit and sits at the top of it.

This significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

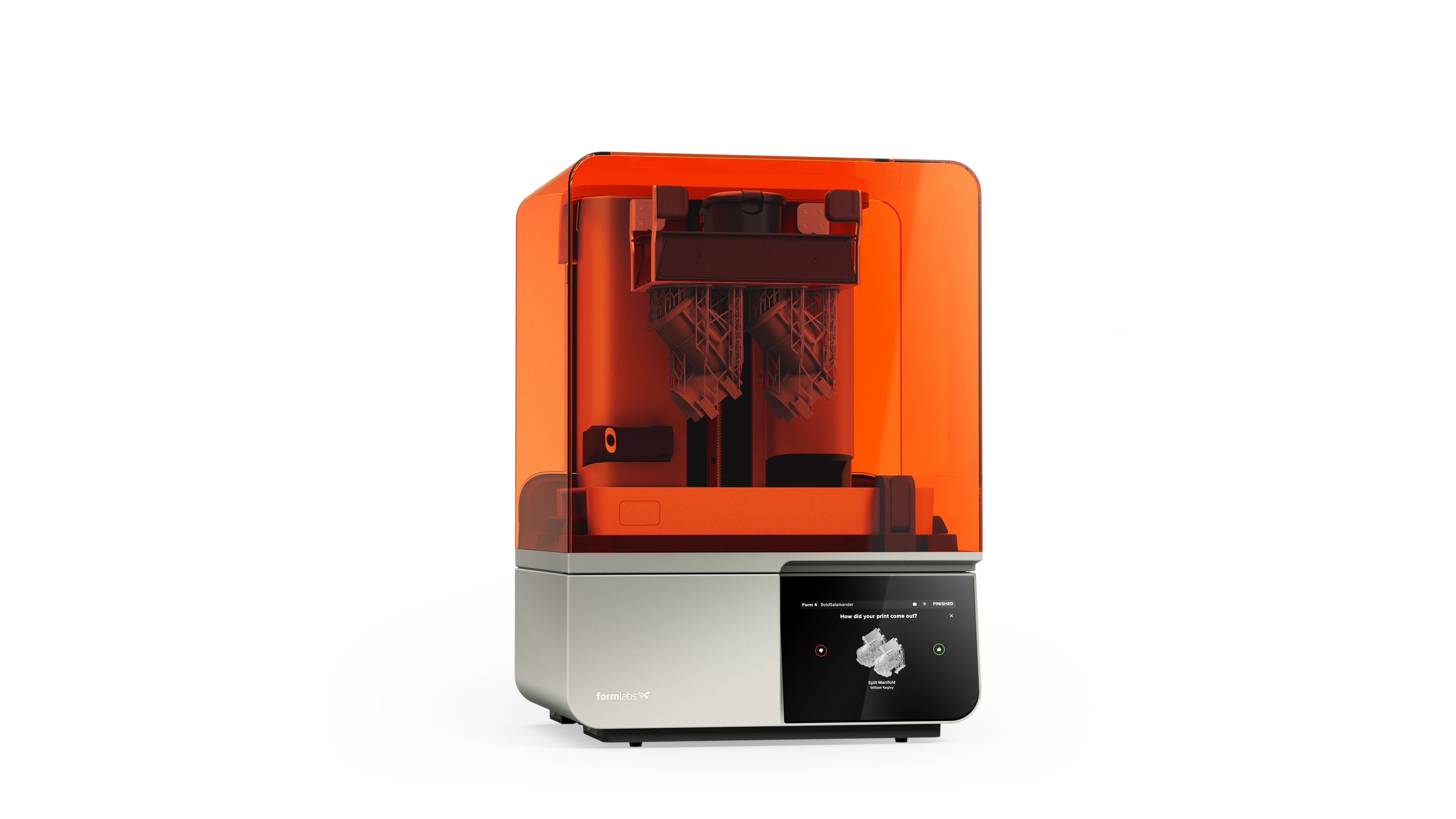

Six onboard control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer.

Together, they ensure consistent, reliable performance and prevent common failures, for the same results on every printer and every print.

Camera enables remote monitoring and troubleshooting, but can be disabled for privacy.

Together, they ensure consistent, reliable performance and prevent common failures, for the same results on every printer and every print.

Camera enables remote monitoring and troubleshooting, but can be disabled for privacy.

The Form 4 Resin Tank holds liquid resin inside the printer and provides a substrate for the liquid resin to cure against, using a dual-layer flexible film stack.

It significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

It significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

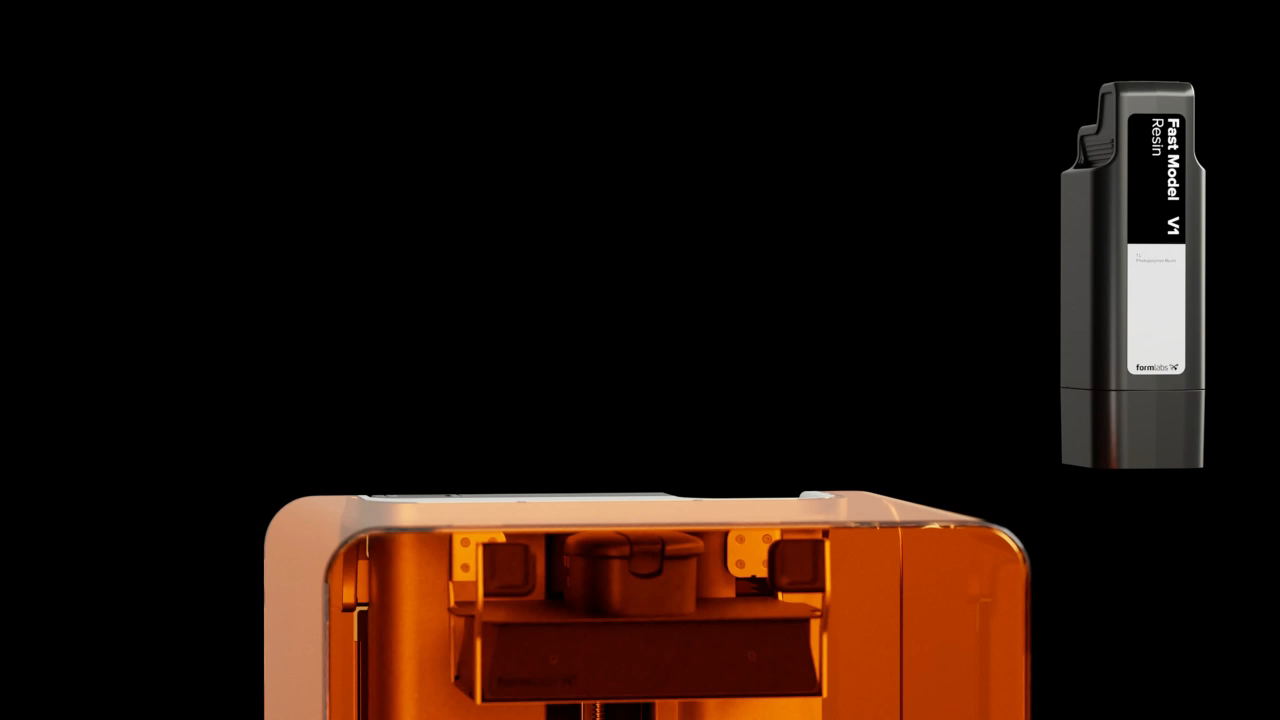

Integrated system that dispenses resin quickly, accurately, and with minimal waste, while making it easy to switch materials.

Print without having to worry about your printer running out of resin and switch materials in <1 minute.

Form 4 is still one of the only SLA printers on the market to offer this feature.

Print without having to worry about your printer running out of resin and switch materials in <1 minute.

Form 4 is still one of the only SLA printers on the market to offer this feature.

Take a 3D tour

of the Form 4

of the Form 4

2'699.- CHF

starts at

Form 4

2'699 CHF

starts at

Form 4